The Penn Tool catalog says that usually the mandrel is inserted using an arbor press. This seems a bit extreme to me, but then again if it wasn't tight the part would spin on the mandrel. So how much force do I need to use to insert the mandrel? Roughly what type of accuaracy can I expect using these types of mandrels?

Add to Cart for Special Price SHIPS FREE Orders must have $49 of Free Shipping products to qualify for shipping discount. Additional charges for Non Free Shipping products, products shipping to remote locations, HazMat products, and large or heavy items still apply.

Price : Get Quote Hydraulic Expanding Mandrels : jelly mandrels 6 : 350 We are offering hydraulic expanding mandrels. concept-hydraulic clamping systems the advent of concept-hydraulic clamping system opens new ways in mastering the most difficult situation with uncompromising thoroughness.

.6875" dia. solid aluminum 1.375" long with cable loops on each end.

Using an expander mandrel prior to neck turning sizes the case to fit the neck turning mandrels perfectly. This correct fit makes the turning process more precise and much easier. Any of the mandrels can be used to ""neck"" cases up to the next caliber when used with the NT-EXP (Expander Body).

ROYAL CNC EXPANDING MANDRELS 1.Choose the appropriate body assembly. q The body provides a precision interface for connecting the mandrel to the lathe spindle. q Assembly includes body, custom-machined drawtube connector, and mounting hardware. q Order mandrels, sleeves, and part locators separately.

Rs 22,000 Get Latest Price We have become one of the leading manufacturers and suppliers of a superior quality range of Expanding Mandrel. These are fabricated using high grade components which are finely tuned to produce high-precision concentric expansion along the datum line of the machine.

Larger Bending Mandrel Set includes two tools that include diameters of 1.6, 2.6, 3.6, 4.6, 5.1, 6.0, 7.0, 8.0, 9.0 and 10.0 mm. See More See Less WARNING: This product can expose you to chemicals, including Lead which is known to the State of California to cause cancer or birth defects or other reproductive harm.

This is Mandrel Nylon from Mandrels produced by . Call us at +44 1793 848 123 and get a qoute.

Tube bender operators could rely on complex mathematical formulas and rules of thumb, but it’s much quicker to use a tooling chart. This sort of chart lists the two main bending criteria, D of bend and wall factor, on the X and Y axis, respectively. However, these charts have just two axes, and usually are based on bending mild steel to 180 degrees. Tube bending comprises many more variables

Expanding The Expanding Mandrel's Usefulness This expanding mandrel is designed to locate and hold thin-walled parts on the ID to avoid distortion during precision machining. It can also be used to hold heavy parts with large bores for heavy machining operations.

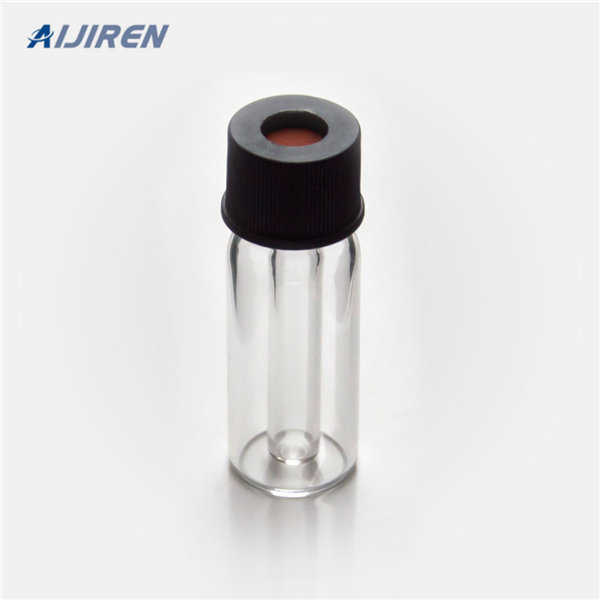

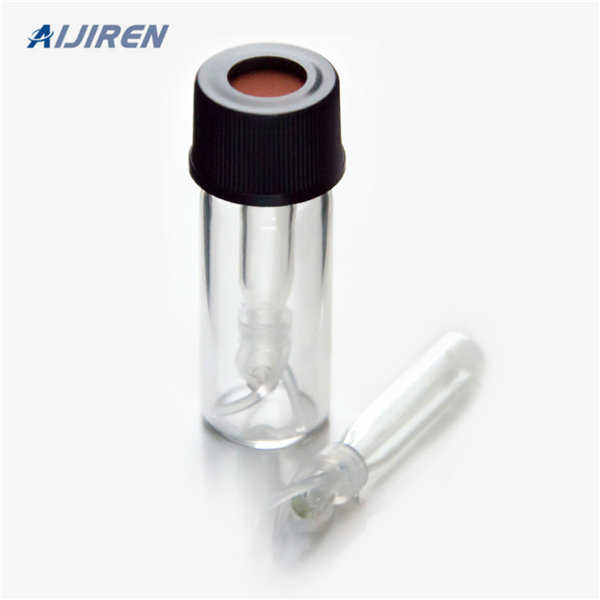

150ul Insert with mandrel interior and polymer feet, 29*5mm; suits for ND8 Vials: IP250: 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials: I250: 250ul Micro-Insert,31*5mm,clear glass,flat bottom; suits for ND8 Vials: I300: 300ul Micro-Insert,31*6mm,clear glass,flat bottom; suits for ND9 Vials: V181

What makes our mandrel bends different is the tubing we start off with. Made from an American made mild steel and bent in the U.S., they are the best mandrel bends on the market. 1 5/8" 45 Degree 2.5 CLR Mild Steel Bend

Miniature MICRO 4 Jaw Chuck Mandrel adapter, with a holding capacity range of 0 to 1.00mm drills and accessories. (The 3rd and 8th pictures show the chuck holding 1 mm thick wire) Mandrel shank has two holding diameters (a 1/8" and 3/16" Shank), the main body portion measures 3/16" and the shank end is 1/8" adapter can be held at either diameter.

You have no items in your shopping cart. Quick Order. SKU: Qty: