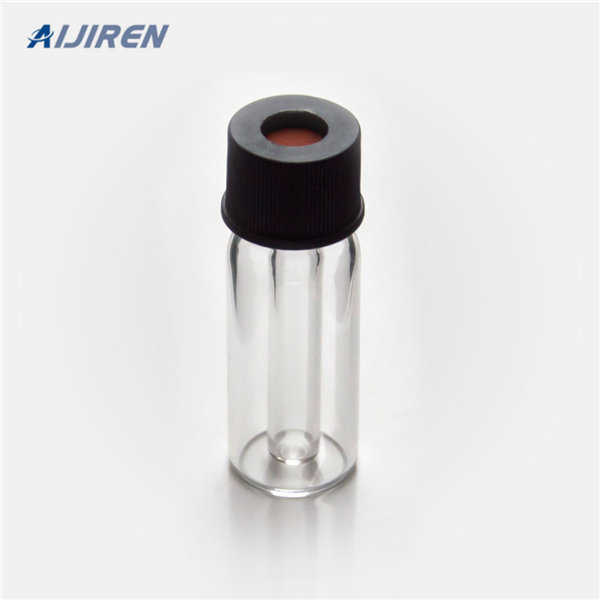

150ul Insert with mandrel interior and polymer feet, 29*5mm; suits for ND8 Vials: IPB250: 29*5.7mm: 100PCS/PK: 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials: IPB250-P: 29*5.7mm: 200PCS/PK: 250ul Plastic Insert with mandrel interior and polymer feet,suits for ND9 Vials : IA250: 31*5mm: 100PCS/PK

150nm. Such materials have been adapted for manufacturing tool inserts for polymer microfluidics by using micro-manu-facturing technologies (table 1). • Stainless steel and brass can be machined using various micro-manufacturing technologies with high aspect ratios with a user-defined draft angle; however, the micro-

In recent years, fabrication of polymer based micro components for optical and biomedical applications has gained increasing attention [1]. Micro-molding of polymer-based materials has the advantages of low cost, good biocompatibility, high optical clarity and high impact strength. Hot embossing and micro injection molding are the most

Manufacturing core and cavity insert Guideline When we manufacture the core and cavity inserts during the mold manufacturing , there are some dimensions that we need to manufacture with some tolerances so that it fits well in the pocket of the insert plate or cavity/core.

Jul 01, 2012 · The manufacturing process of the mandrel tool was configured based on the installed capacity of the special punching tools and forging facilities. In this sense, it was essential to consider the previous design specifications obtained to satisfy the conditions for the application of this new mandrel tool, fastening devices and cutting tools

Precision Cold Forming and Micro Manufacturing When most people think of micro manufacturing, images of computer chips and circuit boards come to mind. These technologies were just the beginning of a revolution to make parts of all types smaller and more robust.

Interior Glazed: Glazing infills set from the interior of the building. Interior Stop: The removable molding or bead that holds the lite in place when it is on the interior side of the lite. Interlayer: Any material used to bond two lites of glass and/or plastic together to form a laminate.

polymer process where the IM tool cavity itself is a high temperature polymer insert fabricated through HE. The insert production can be done using this two-step replication method or using direct structuring micro manufacturing processes, bringing flexibility on achievable features based on cost effectiveness and process capabilities.

manufacturing was rather complex and involved micro electrical discharge machining of a Silicon wafer (to create the master geometry), followed by PVD and electroforming of a Ni counterpart. This Ni shim was finally used as an insert in an injection moulding process to create polymer micro fluidic systems.

The high-cost, high-performance amorphous resins are resistant to hot water and steam, and are rated for high temperature applications, up to 300 degrees F. They have high thermoformability and high strength. Plastics in this category include: Polyphenylsulfone (PPSU, a.k.a. Radel R®) Polyetherimide (PEI, a.k.a. Ultem®) Polysulfone (PSU)

These premium abrasives are designed for automotive refinish sanding of primers, fillers, and clearcoats, as well as metal and non-ferrous substrates. They provide fast cutting action, with the durability and load resistance only available through modern technology.

Caps are made of high quality polypropylene to exact manufacturing tolerances and lined in a controlled manufacturing environment. KR150 - 150µl insert with mandrel interior & polymer feet. Suits for ND8 Vials. KR250 - 250µl with mandrel interior & polymer feet. Suits for ND9 Vials. K250 - 250µl Micro-insert, flat bottom. Suits for ND8 Vials.

Our manufacturing facility utilizes scientific injection molding principals incorporating cavity pressure transducer technologies ensuring our customers the highest quality parts. Transducer technologies quantify the proper injection pressure and injection velocity, and accurately compensate for any change in viscosity of the resin during the

the manufacturing process is an important consideration. Injection molding is a process in which solid thermoplastic resin pellets are melted, injected into a mold, and then cooled back to a solid state in a new form. During both the injection and cooling stages of the manufacturing process, there are several factors

1. Introduction. Microparts and microsystems technology is reputed as a prospective key technology with an estimated annual growth rate of about 10% [].The main fields of application of polymer microparts are seen in the areas of medical technology, as components of optical systems, as microgears in microfluidics, biotechnology, and electronics, or as a microelectromechanical system [2, 3].